Products

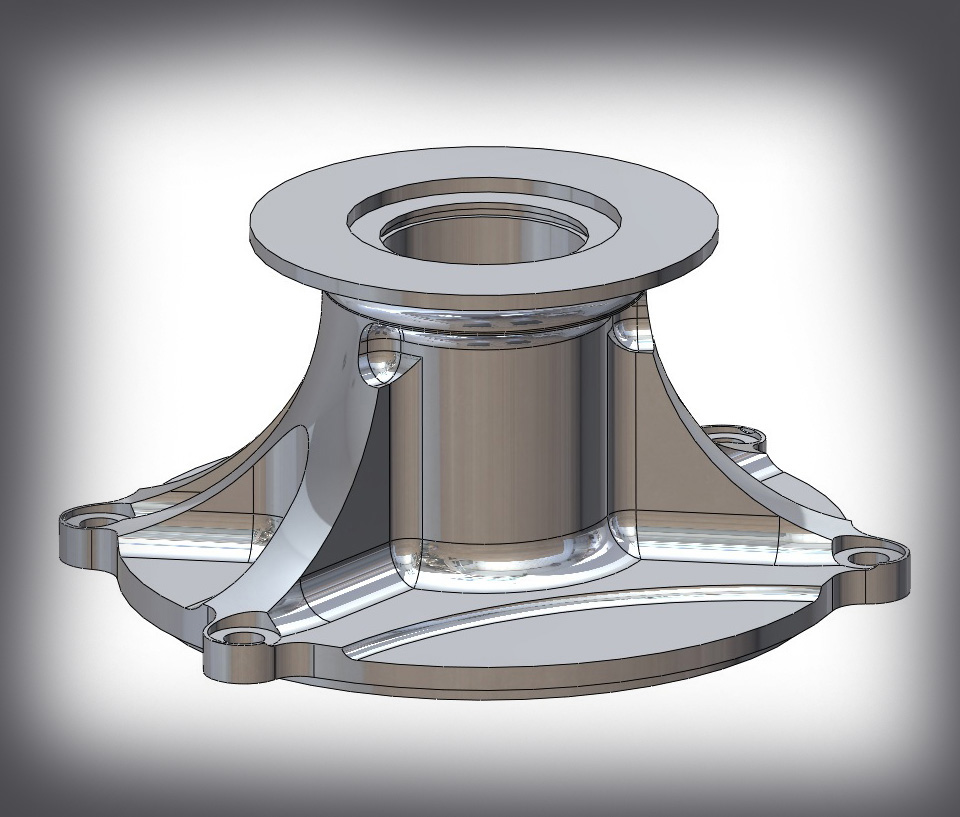

Tool Design and 3D CAD Modelling

Proven ability in designing of simple and complex injection moulds. We design tool and moulds for faster and simplified manufacturing, to suit your production volume requirement and budget.

Complex undercut moulding with the use of Mechanical, Hydraulic or Air operated slides /Angle lifts /Sprung core /Collapsible core.. Manual or automatic unscrewing moulds.

Design & Manufacturing of injection moulds with very complex 3D Parting lines and Blank off surfaces are our speciality. Due to non-disclosure agreement we are unable to give details of our achievements in this area.

Good Tool making start with Good Tool designing. Often people don’t have time to think of good design or to discuss design input, but has a lot of time to fix a bad tooling resulted from a poor Tool design.

Design for Manufacturing :

It is very important that parts are designed and modelled with manufacturing intend. We will assist you in choosing the right polymer and review the feasibility of your part for injection molding. Suggest changes and modification to your part for proper draft, gate location, under cuts, wall thickness , sink. This process simplifies the mould design with out compromising on any functional and cosmetic requirement of the product. We have in house Tool design and CAD modelling facility. More over easy access to external resources when there is a capacity shortage Our design focuses on how to.

- Get the material in

- Get the air out

- Get the heat out and

- Get the part out

Tool Making

With years of experience, supported by the new CNC machines and upgraded facilities we are confident that Prime tooling can meet your quality and delivery requirements. For more information please contact us. The company currently employs 7 tradesmen and “uses 2 seats of Master Cam etc..” with “ uses 3 seats of the latest CAD/CAM software for designing and toolpath programming”. We have in house injection moulding facility up to 128T, to try out plastic injection moulds. We trial most of the new moulds before sending it to our customers.

We manufactures precision toolings for:

- Automotive industry

- Electrical, electronic and computer equipment

- Medical equipment

- White goods industry

- Horticultural market

- Home/leisure products

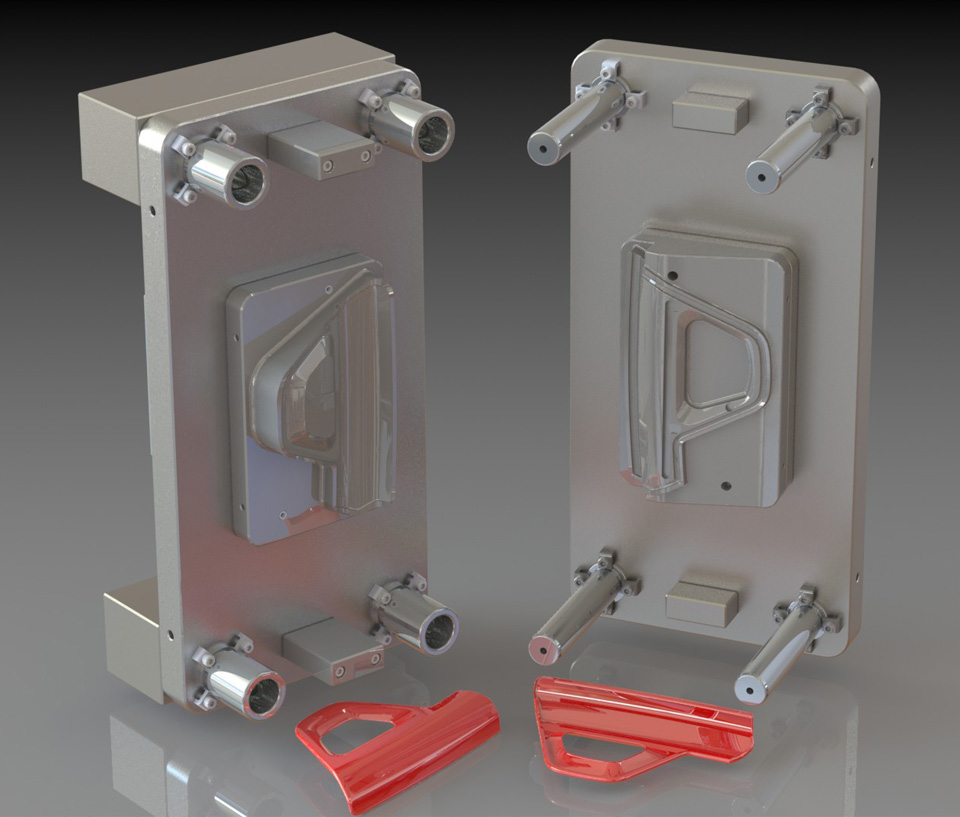

Mould / Testing

We have in house injection moulding facility up to 128T to trial all plastic injection moulds manufactured by us. With consent from our customer, we trial most of the moulds prior to sending it to them. This ensures moulds are production ready before dispatching it to customers. More over initial product evaluation could be done using these OTS ( Out of Tool Samples-T0) produced in house and if required, further modification on the part or product could be planned and included. This saves a lot of time and money in transport and waiting for tool trial resulting in an early product launch.

Many customers find it advantageous to be able to have short runs prior to mass production, giving them the opportunity to experiment with materials, of which we have a wide and varied stock.

Tools are first tested in a production environment to provide an accurate and comprehensive performance assessment to ensure that they meet the customer’s specification. We believe this often saves considerable development time and cost, which provides a commercial advantage in helping reduce product launch lead times.

Machines in our moulding shop are

- 1 x 128t Capacity

- 1 x 100t Capacity

- 1 x 60t Capacity